|

|

| |

|

|

|

Products. |

|

|

|

|

Particle

Separator: |

|

FAA

certified particle separator: |

|

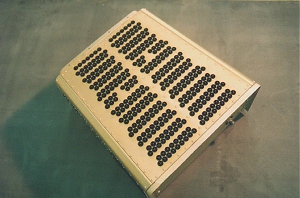

In conjunction with a long term commitment to improve the performance

of the MDHI 500 series helicopter, E.M Heli-Logistitcs Ltd. is

introducing a high efficiency engine air inlet particle separator.

The new separator installation certified by Heli-Logistics and manufactured by Pall Aeropower Corp.,

of Clearwater, Florida, received a Supplemental Type

Certificate (STC) #SR00469SE from the Federal Aviation Administration

(FAA). The particle separator features a new 3 sided design that enables

more efficient particle separation and improved airflow characteristics, by

increasing the engine air inlet area by 74%, and

increasing clean air to the compressor by 50%. The end

result is lower engine maintenance costs due to a reduction of foreign object damage (FOD),

erosion and contamination. The new design incorperates the *Centrisep Air

Cleaner.

|

-

Reduces engine maintenance costs:

revised air cleaner

configuration

reduced FOD risk

fewer components in clean air space

- Virtually Stops

engine flame-out Due To:

snow ingestion

ice ingestion

- Increases

performance:

improved high altitude, hot day performance of the

engine.

|

|

|

AMOC (Alternate Means of Compliance) - in

response to a Transport Canada issued Airworthiness

Directive #CF-200-23, Heli-Logistics received an AMOC

for the particle separator installation.

|

|

- Other features:

incorporation of cockpit warning system to

advise of partially clogged separator

- Quick and easy

to remove for:

- separator cleaning

- in-take inspection

- maintenance

|

|

Once installed, the particle separator becomes part of the

air inlet fairing structure, incorporating twin rear injection

scavange air ports for improved contamination removal without

the increase of engine turbine outlet temperature. By increasing

the flow capacity of the new separator, strategically locating

the three filtration areas and improving air scavange, the high

altitude, hot day performance of the engine is improved. More

efficient particle separation reduces erosion to engine components.

The new separator configuration potentially eliminates engine

failure caused by sudden ingestion of snow or ice, or inlet blockage.

Additionally, in the new configuration, the separator by-pass

door and all associated hardware have been removed, reducing

the possibility of FOD. The separator is quick and easy to remove

for cleaning and provides unrestricted inspection of the compressor

inlet area.

*Centrisep is a registered trademark of Pall Corporation |

| Copyright 2007

E.M. Heli-Logistics Ltd. All Rights Reserved |

|

|

|